All rights reserved © 2008 Super Alloy Technologies Co., Ltd |

ISO 9001 : 2008 Certified |

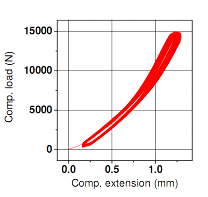

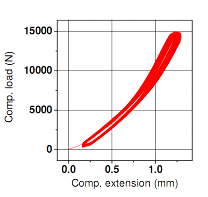

Thornton Driver 400 at 3,565 cycles compression test |

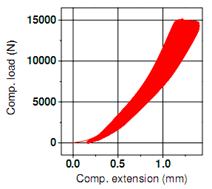

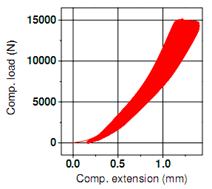

Thornton Driver 460 at 3,000 cycles compression test |

All rights reserved © 2008 Super Alloy Technologies Co., Ltd |

ISO 9001 : 2008 Certified |

Thornton Driver 400 at 3,565 cycles compression test |

Thornton Driver 460 at 3,000 cycles compression test |